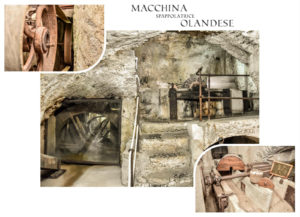

The knitted pile in which much of the work was still handmade, was replaced by the Dutch machine installed in the Milan paper mill on 18 November 1745, as can be seen from the date graffiti on the wall and in which, in addition to refining, the rags were also washed and frayed. The Dutch pile was a machine consisting of a tank of stone and cement with an oblong shape.

Dutch Machine

A median wall divided the tank into two channels communicating with each other: in what was usually kept wider, and which was called the working channel, rotated a cylinder supplied to the surface of blades arranged according to the generators of the cylinder itself. On the sloping bottom was the sinker, a system of knives held together by screws and separated from each other by thin wooden walls so that they always remained protruding while wearing out. The plate was fixed in a cast iron box which was introduced into the Dutch machine, under the cylinder, through an opening made at the side of the machine itself and could be perfectly closed.

The Dutch stack was therefore able to work faster and at a lower cost than the hammers and was mainly made up of a fixed part of the plate and a mobile part of the cylinder which could be moved vertically by means of a handwheel, a lever system; in this way it was possible to vary the distance of the blades from the cylinder to the fixed ones of the plate at will.

But what if a part of this very important tool for handmade paper production had to fail or malfunction?

Dutch machine detail

The paper mill intervened, and this adds value and importance to its figure, directly to repair the inconvenience, with great competence and “technical” knowledge of what was the functioning of all the components of the paper mill.

For this reason, a special workbench was used where it was possible for the paper manufacturer to develop the tools and mechanical parts necessary for the long work of those who produced paper by hand.